The Planetary Tuning Forks

The original, from the developer of the Cosmic Octave:

Tones of Sun, Moon, Earth and Planets.

For Planetware offers of individual tuning forks and sets please click here.

Notes about using the planetary tuning forks down here

• Tuning fork versions

• A Tuning Forks should be in tune

•

High-quality Steel vs. Aluminium

• Handling the tuning forks

In 1978 the Swiss mathematician and musicologist HANS COUSTO discovered the natural law of the "Cosmic Octave"; this links a variety of natural phenomena which occur periodically, such as of the orbits and rotations of the planets, the weather, colours and musical rhythms and tones.

Using the octave formula f x 2n (= n-fold doubled frequency), he calculated the tonal frequencies of the orbital and rotational periods of the earth, moon and planets, and later also the octave tones of various molecules.

Since that time Fritz Dobretzberger has been working closely with Hans Cousto. In 1989 he founded the company Planetware to inform about the Cosmic Octave and to offer tuning forks and other instruments for practical use.

All Planetware tuning forks are made from the highest quality steel to provide the most consistent vibration response with the highest frequency accuracy. The following description of the Planetware tuning forks allows a comparison to be made with other tuning forks available on the market.

This tuning forks are superb for precise attunement to the naturally ocurring frequencies of nature and life; they are used for tuning music instruments as well as in sonopuncture, which brings our body and soul into tune with the universe.

NEW:

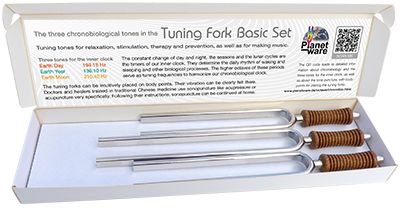

Tuning Fork Basic Set

Order Basic Set Splus Order Basic Set Lplus

3 tuning forks for our inner clock: Earth day, earth year, earth moon.

For information on the chronibiology of the inner clock and sonopuncture with the corresponding tuning forks, please click here.

The tuning forks are available in various versions

Tuning Fork S

Tuning Forks for occasional usage at home

• Made of nickel-plated high-quality special steel with a mirror-smooth surface.

• Fork arms of 4 x 8 mm with softly rounded edges

• Welded-on fork foot with thickened foot end

• Stamped frequency number on the tuning fork base

For Planetware offers of individual tuning forks and different sets please click here.

Tuning Fork Splus with ergonomic handle

For a relaxed, ergonomic usage

An improved “S” tuning fork with the same prongs (and same note precision) but a longer and ergonomically designed soft grip handle making it easier and more comfortable to use during sonopuncture.

The soft grip is made of cork with a elastomer (TPE) coating.

On the side of one prong there is a high-contrast inscription denoting the fork model and pitch.

For Planetware offers of individual tuning forks and different sets please click here.

Tuning Fork L

For frequent and professional usage

Intricately cut from a single piece of stainless steel and nickel-plated (a smooth matt finish). Prongs with chamfered edges all round.

They are about 60% heavier than the S version and resonate as long and therefore do not need to be struck as often during prolonged professional use.

High-contrast inscription denoting the frequency and planet.

For Planetware offers of individual tuning forks and different sets please click here.

Tuning Fork Lplus with ergonomic handle

For frequent and professional usage

Similar like the version L plus an ergonomic handle.

The ergonomically designed soft grip handle makes it easier and more comfortable to use the tuning forks during sonopuncture. The soft grip is made of cork with an elastomer (TPE) coating.

For Planetware offers of individual tuning forks and different sets please click here.

A Tuning Forks should be in tune

The prongs of the “Splus” tuning fork resemble those of the “S” model; the vibration behaviour is identical as is the note precision. So the accuracy of the frequencies of all types of tuning forks offered by Planetware -— of course types "L" and "Lplus" as well — is high as possible. Since the autumn of 1978 when Hans Cousto identified the frequencies of the Earth, moon, planets and sun we have placed great value on the highest quality.

A short anecdote from those days serves as proof: The first tuning forks delivered from the factory were only of DIN standard meaning some forks had a deviance of up to 1 Hz from the specified frequency. We returned these tuning forks assuring the manufacturers that a difference of 1 Hz in the octave of the Earth’s rotation would make the terrestrial day approx. 7 minutes shorter than it actually is (In fact, the length of Earth's day has increased by less than 1/10 of a second over the last 3,000 years).

In order to achieve the most even vibration behavior and the highest possible tuning accuracy, all tuning forks offered by Planetware are made of high-quality nickel-plated steel. For the models S and Plus it is so-called gong steel and for the models L and Lplus a special tool steel. To prevent the steel from rusting, the tuning forks are nickel-plated. The main reason why stainless steel is not used is that stainless steel is much tougher, so the tuning fork would have a shorter oscillation period.

High-quality Steel vs. Aluminium

Whether for tuning or sonopuncture, the highest possible resonance is of the utmost importance for frequency precision. Planetware's tuning forks, made of high-quality steel, offer this high precision.

Compared with aluminium tuning forks, those made of steel have a more stable frequency deviation arising from temperature differences, which is especially important in their use in sonopuncture. During this process tuning forks are held in the hand for longer periods leading to their heating up. The change in frequency in stainless steel tuning forks caused by this temperature difference is minimal compared to that produced in aluminium tuning forks that expand more when heated, thus changing the note.

Handling the tuning forks

![]()

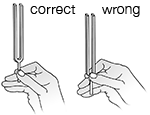

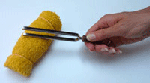

The ergonomic grip pad of the tuning fork models Splus and Lplus from Planetware enables a sustained relaxed use. The shape and material of this grip pad allows the tuning fork to be held more loosely. To strike the tuning forks, hold the shaft or grip pad with thumb, index and middle finger and strike the end of one of the two fork arms against an object with a little swing from the wrist.

When holding on to the shaft of the tuning forks without a grip pad, the fingers should not touch the curvature where the shaft merges into the two fork arms, so that they can vibrate freely and longer.

The tuning fork can easily be struck on the ball of the other hand. Or it can be struck on an object that has about the softness of a hand ball. In any case, it should not be struck on hard objects, as otherwise an undesirable high overtone - a soft whistling tone - will emerge.

TIP: A rolled-up small towel is well suited, the roller lashed at both ends with two cords. If the cords are not tightly knotted, or two Velcro straps are used, the towel can be used to wrap one or more tuning forks in it for transport.

After striking the tuning fork, the fork arms vibrate back and forth at the appropriate frequency. The back and forth movement of the fork arms is transferred to an up and down movement of the tuning fork stem via the lower curvature. By placing the stem of the vibrating tuning fork on the body, the vibration is transferred there in its frequency.